Scanning Microwave Microscopy for the Semiconductor Industry

This application note explores the use of Scanning Microwave Microscopy in the semiconductor industry, highlighting its pivotal role in the analysis of semiconductor devices. Since its introduction in the early 2000s, this technique has become essential for examining the electrical characteristics of semiconductors with high precision and sensitivity.

Key learnings:

-

Scanning Microwave Microscopy in Semiconductor Analysis: Understand how this technique has revolutionized the analysis of semiconductor devices by enabling precise measurement of electrical characteristics.

-

S11 Measurement Mode: Learn about the S11 measurement mode, used for assessing dopant density and dielectric constants in insulating materials, and the importance of calibration in this process.

-

dS/dV Measurement Mode: Explore the dS/dV measurement mode, its role in identifying dopant types, and its advantages in minimizing topographic cross-talk and detecting changes in dopant types.

-

Applications in Quality Control and Fault Inspection: Discover how both S11 and dS/dV modes contribute to quality control and fault inspection in semiconductor structures, providing distinct contrasts and insights.

-

Significance in the Semiconductor Industry: Recognize the importance of Scanning Microwave Microscopy as a non-destructive tool for defect localization and quantitative doping profiling, crucial for research, development, and manufacturing in the semiconductor sector.

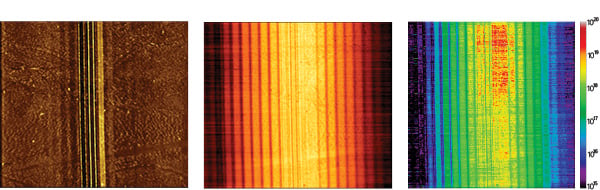

Measurement of the Infineon SCM sample made in dS/dV mode: (a) dS/dV amplitude and (b) dS/dV phase. The dS/dV phase shows distinct difference between two different doping types – n and p. Scan size: 40 x 40 μm2.